-

By AdminWhy Batch Consistency Breaks Down in Aluminum Profile MachiningBatch problems rarely announce themselves with a clear failure. More often, they appear as mixed signals. One operator flags a finish change. Another notices hole depth feels inconsistent. Measurements still pass on paper, but confidence drops. In aluminum profile machining, this is how batch consistency starts to break down—not because the program is wrong, but because the process no longer behaves the same from part to part. This kind of variation is hard to diagnose because nothing is completely out of tolerance. Instead, small shifts in clamping, temperature, material response, and reference position combine over time. What looks like a…

-

By AdminWhy Aluminum Profiles Lose Length Accuracy After CuttingJust image you cut a batch of aluminum profiles to length, and the first few pieces look fine. Then the numbers start to drift. One part is 0.3 mm long, the next is 0.6 mm short, and suddenly the “same program” feels like a moving target. In most shops, this is not a blade problem. It is a process problem that shows up after cutting, when the profile gets moved, re-clamped, and machined in steps. Length Problems Rarely Start at the Blade A saw cut can be clean and repeatable, yet your final length still ends up off. That sounds…

-

By AdminWhat Industrial Buyers Should Expect From an Aluminum Profile Cutting Saw ManufacturerIndustrial buyers rarely search for an aluminum profile cutting saw manufacturer because they want a “machine with a fast cut.” They search because they want stable output. In real production, the cutting station decides whether parts locate consistently, whether downstream CNC work stays predictable, and whether operators spend their shifts making parts or chasing offsets. If your supplier only talks about speed and basic specs, you are not evaluating the risk that matters most: variation that grows across a batch. This guide explains what you should expect from an aluminum profile cutting saw manufacturer when your goal is repeatability, not…

-

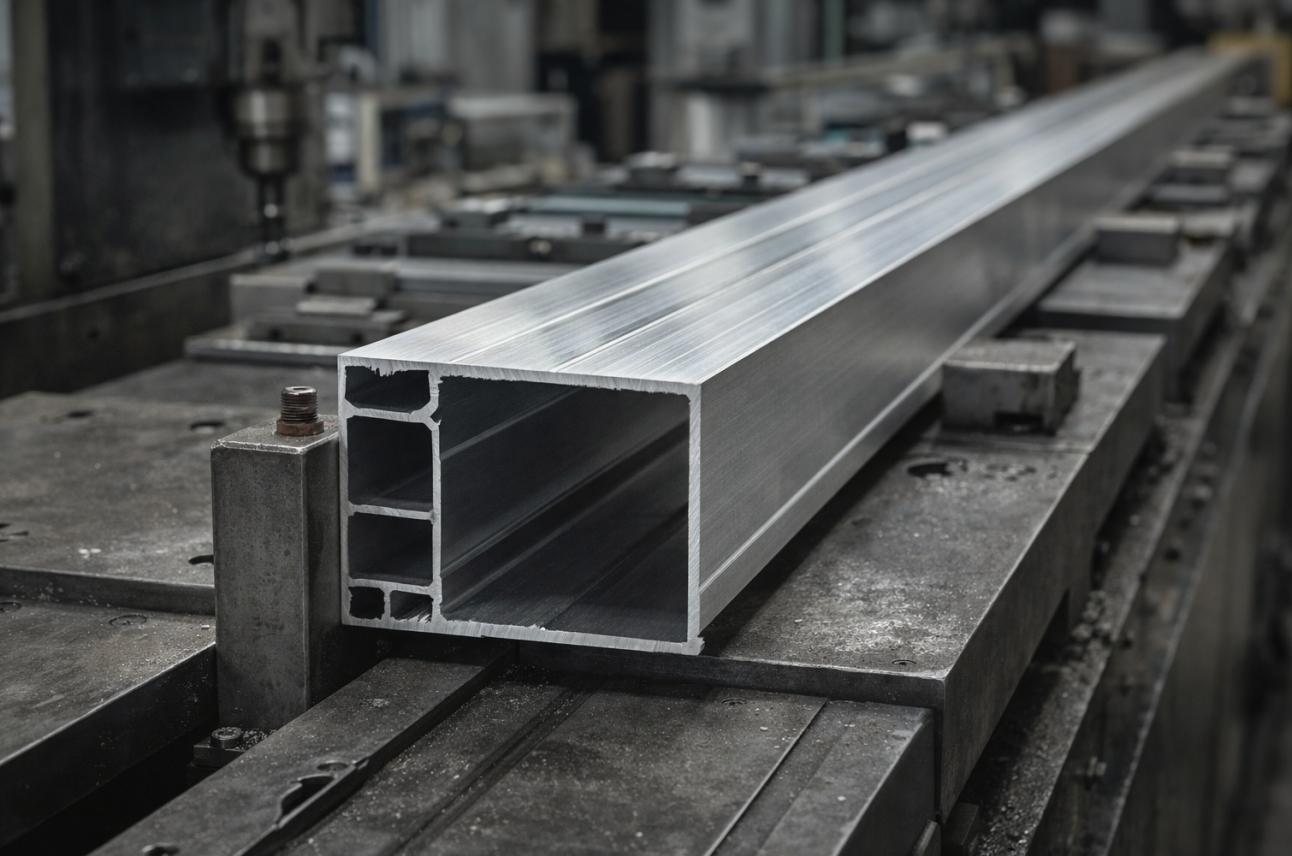

By AdminHow Aluminum Profile Machining Lines Are Built: From Cutting to CNCMachining line for aluminum profiles fails in a familiar way. Cutting reports look acceptable, the CNC program looks proven, and the first pieces can measure fine. Then the batch starts drifting. Operators begin nudging stops, tweaking offsets, and “saving” parts with clamp force. At that point, it is not a machine problem. It is a process-link problem. If you are building an aluminum profile machining line, the job is to keep reference surfaces consistent from cutting to CNC. The line must protect datum continuity, control long aluminum profile support, and create feedback loops that correct issues at the right station…

-

By AdminWhy Cutting Errors Break CNC Accuracy for Aluminum Profiles (And How to Stop the Tolerance Stack-Up)If you have ever checked a cut batch and thought “these lengths look fine,” then watched the first CNC run drift out of spec, you already know the trap. In real production, cutting errors aluminum profiles are rarely a single dramatic mistake. They are small geometric and handling deviations that survive inspection and then multiply across setups. That multiplication is the tolerance stack-up, and it is the fastest way to lose CNC accuracy aluminum profiles even when your operators are careful and your programs look correct. This article focuses on the practical chain: how cutting quality feeds your datum, how…

-

By AdminAluminum Profile Cutting Accuracy: What Affects Tolerance and How to Improve ItIf aluminum profiles are your daily bread, cutting accuracy is not a “nice to have.” It decides whether parts slide into jigs smoothly, whether hardware holes land where they should, and whether the CNC stage feels easy or painful. A small length drift or a slightly off-square end can look harmless at the saw. Then assembly starts, and suddenly everyone is “checking one more time.” This article breaks down aluminum profile cutting accuracy in plain shop terms: what the key tolerances really are, why they drift in production, and what actions actually move the needle. You will also see how…