Aluminum Profile Cutting Accuracy: What Affects Tolerance and How to Improve It

If aluminum profiles are your daily bread, cutting accuracy is not a “nice to have.” It decides whether parts slide into jigs smoothly, whether hardware holes land where they should, and whether the CNC stage feels easy or painful. A small length drift or a slightly off-square end can look harmless at the saw. Then assembly starts, and suddenly everyone is “checking one more time.”

This article breaks down aluminum profile cutting accuracy in plain shop terms: what the key tolerances really are, why they drift in production, and what actions actually move the needle. You will also see how cutting errors can quietly ruin later drilling and milling, even if your CNC program is fine.

What Cutting Accuracy Means on Real Aluminum Profiles

Cutting accuracy is not one number. It is a bundle of small conditions that stack up into fit, function, and yield. When people say “the cut is off,” they often mean different things, so it helps to name them.

Key Tolerance Types You Actually Care About

For most profile factories, these are the big ones:

-

Length tolerance: the part is too long or too short.

-

Angle tolerance: a 45° is really 44.6°, and now corners fight you.

-

Squareness of the end face: the end looks flat, but it is not square to the profile axis.

-

Straightness after cutting: long parts can spring, sag, or twist once they are freed.

-

Burr and edge condition: not just “looks,” but whether burrs change how parts sit on stops.

These are the tolerances that decide whether downstream fixtures repeat well and whether the aluminum profile yield stays healthy.

Typical Tolerance Ranges and What They Cost You

There is no one universal “correct” cutting tolerance for aluminum profiles. The range depends on what the cut is for. A decorative trim might tolerate more variation than a hardware-critical mullion. What matters is the rule behind the rule: tight tolerances cost time and money, so tighten only where the function demands it. If every dimension is treated as critical, the line slows down and scrap rises. It happens fast, then you see it in your weekly numbers.

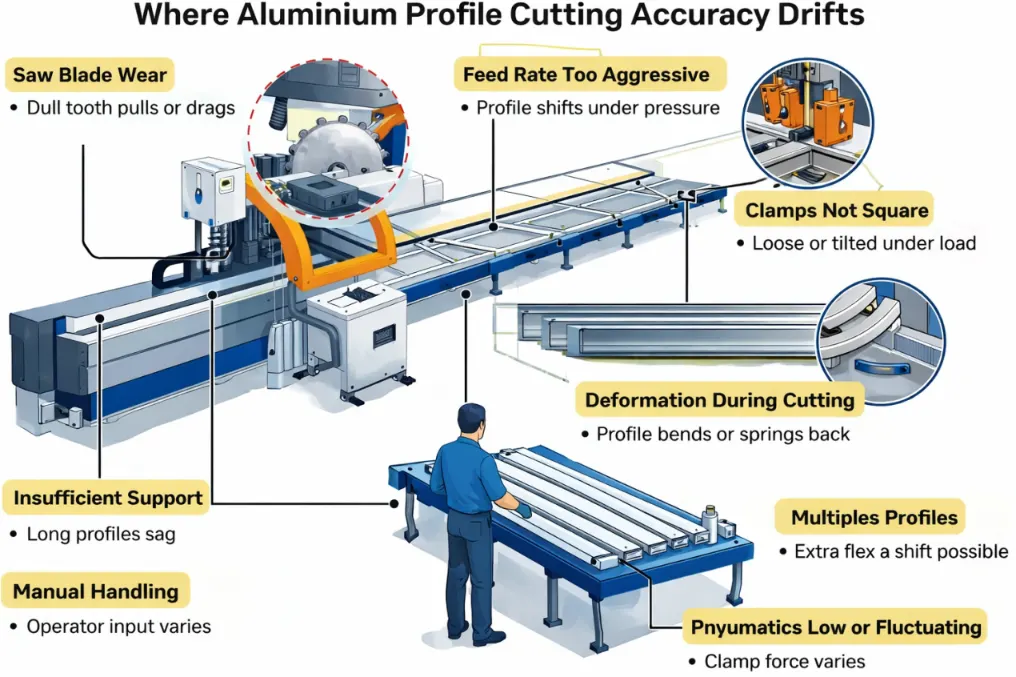

Why Aluminum Profile Cutting Accuracy Drifts in Production?

If aluminum profile cutting accuracy looks good in the morning and drifts by late afternoon, that is normal. It is also fixable. Drift usually comes from three buckets: the profile itself, the saw process, and the way the line is managed.

Material and Profile Factors

Long, thin-wall profiles behave like long rulers. They bend. They twist. They also release stress when you cut them. Some batches spring more than others, even when the same program and stops are used. Hollow sections are especially sensitive. A small clamp force change can distort the wall, and suddenly the end face is not square anymore. If you work with cutting accuracy for window and curtain wall profiles, you have probably seen this: the profile “looks” straight, but the jig says no.

Saw and Process Factors

In many plants, the aluminium profile cutting saw is the first source of tolerance drift, especially when blade wear, feed rate, and clamping are not reviewed regularly.

A few common culprits:

-

Saw blade condition: dull teeth push, heat, and smear. Cuts start wandering.

-

Feed rate: too aggressive can pull the profile, too slow can burn and burr.

-

Clamping: uneven clamps twist the profile. Soft walls get crushed.

-

Chip and coolant control: packed chips can kick the blade off track.

If you want a deeper dive on the saw stage, this guide on aluminium profile cutting saw troubleshooting is a solid companion.

Human and Line Factors

Here is a boring one that causes real pain: changeovers. If stops are moved, then “eyeballed back,” the line drifts even with a good blade. Another classic: no clear record of what worked last time for Profile A versus Profile B. Drift becomes a mystery when it is really just missing habits.

How to Set Tolerances Without Killing Cost?

Tolerances should follow function. If they do not, costs climb and you still do not get better assemblies. This is where many teams get stuck, so keep it simple.

Use Functional Tolerances, Not Tight Global Rules

Ask two questions:

-

Which cut surfaces are used for location in the next step?

-

Which cuts affect visible gaps or hardware fit?

Those cuts get tighter control. Other cuts can be looser. This is the core of how to set tolerances for aluminum profiles without turning every part into a slow, inspected art project.

Watch the Stack-Up Across Cutting and CNC

Cutting tolerance for aluminum profiles is only one slice. The full stack often looks like this:

-

Cut length drift

-

Stop / datum drift in fixturing

-

CNC positioning and tool wear

-

Re-clamping shift (if you flip parts)

Add them together, and suddenly hardware holes are off in assembly. That is how cutting saw errors affect CNC machining, even when the CNC code is clean.

Practical Ways to Improve Aluminum Profile Cutting Accuracy

This is the part people actually use. The actions below are not fancy. They are repeatable.

Fix the Cutting Stage First

If the saw already introduces length or angle errors, no downstream process can fully “heal” them. Start with blade health, clamp alignment, and stable support for long profiles. Pick one or two defect types, then chase those hard for a week. Random fixes feel productive, but they rarely stick.

Control Deformation and Support Long Profiles

Long profiles need support close to the cut. Otherwise they sag, then the blade exits at a slight angle. Add roller stands, support blocks, or a simple adjustable table system. The goal is boring: the profile sits calm and stays put. No bounce, no twist.

Standardize Changeovers and Records

A quick changeover sheet helps more than many people admit. Record stop positions, clamp points, blade type, and what defect showed up last time. This reduces the “start-up scrap” that hits every time a new profile family runs.

Reduce Scrap by Classifying Defects

Scrap classification sounds like paperwork. In practice, it is a shortcut. Track defects in simple buckets:

-

Length out of tolerance

-

Angle off

-

End face not square

-

Burr too heavy

-

Profile bent or twisted

-

Surface scratches from chips

When you see which bucket is winning, the fix becomes obvious. This is also how you protect aluminum profile yield without guessing.

When Cutting Accuracy Is Good but CNC Still Fails?

Sometimes the cut is fine and the parts still do not assemble well. That is the moment to look at holding, datums, and re-clamping.

Fixturing and Re-Clamping Errors

If a profile is clamped three times to machine three faces, each clamp adds a chance for shift. Even a small mismatch in reference edges can move hole patterns. This is why many factories link cutting control to a stable CNC workflow for machining lineal aluminum extrusions, with fewer flips and clearer datums.

The Role of a Profile Machining Center in Keeping Alignment

When parts need multi-face drilling and milling, one-clamp machining helps. Less handling means fewer hidden shifts. It is not about chasing perfection. It is about reducing the number of places where things can quietly go wrong.

Conclusion: A Simple Accuracy Plan You Can Run Every Shift

If you want cutting accuracy to stay steady, keep the plan simple:

-

Check blade condition on a schedule, not by feeling

-

Support long profiles near the cut

-

Clamp evenly, and do not crush thin walls

-

Lock down changeover settings with basic records

-

Run a quick first-piece check for length, angle, and squareness

-

Classify scrap by defect type, then fix the top one first

Do that, and aluminum profile cutting accuracy becomes tells you fewer “surprises,” and more boring, repeatable output. Boring is good.

Where MALIDE Fits in a Stable Cutting-to-CNC Workflow

MALIDE (Foshan Malide Intelligent Equipment Co., Ltd.) focuses on intelligent equipment and process solutions for aluminum profile production. If your factory cares about repeatable accuracy, the real challenge is not one isolated machine. It is the full chain: cutting, positioning, drilling, milling, multi-face operations, and consistent batch control. MALIDE develops profile machining centers, horizontal profile machining platforms, and supporting line equipment designed for the way doors, windows, curtain walls, industrial profiles, and long extrusions are actually processed. The equipment is built around practical needs such as long-travel machining, stable fixturing, chip control, and fewer re-clamping steps, so alignment stays stable from the first piece to the last. For plants moving from manual stations to a more reliable CNC workflow, MALIDE helps reduce trial-and-error on the shop floor and supports a smoother path to consistent output and better yield.

FAQ

Q1: What is a realistic goal for aluminum profile cutting accuracy in daily production?

A: The realistic goal is the one you can repeat all day, not the best cut you ever made. Start with functional needs, then tighten the few dimensions that affect fit and hardware.

Q2: Why does aluminum profile cutting accuracy drift after a few hours?

A: Blade wear, clamp shift, support sag, and changeovers are common causes. Heat and chip buildup can also push the cut off line.

Q3: Does the aluminium profile cutting saw really affect CNC results that much?

A: Yes. Small length or squareness errors from the saw can multiply during drilling and milling, especially when parts are flipped and re-clamped.

Q4: How can you improve aluminum profile cutting accuracy without slowing the line too much?

A: Focus on the top defect type first, support long parts better, and standardize changeovers. Those usually give the biggest gain with minimal added time.

Q5: When should you suspect the problem is fixturing, not cutting?

A: If cut length and angles are consistent, but hole patterns or slot positions still drift, the issue is often datums, clamping points, or re-clamping steps in the CNC stage.